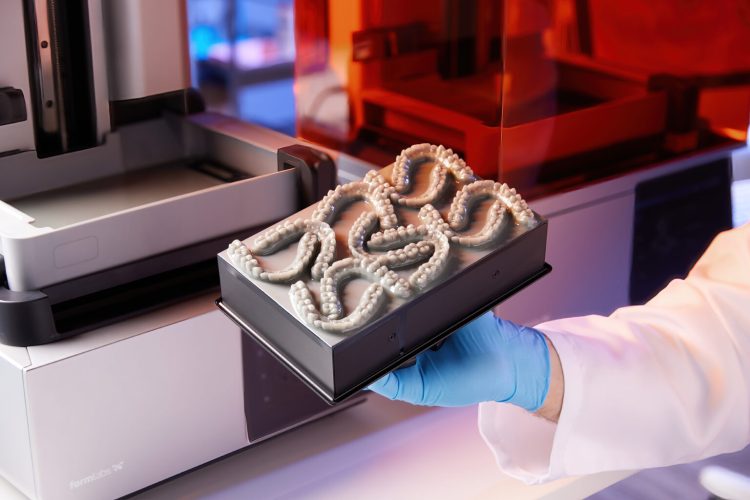

In recent years, 3D printing technology has revolutionized many industries, and the field of dentistry is no exception. From creating highly personalized dental implants to accelerating the production of crowns and bridges, 3D printing has transformed traditional dental processes, making them faster, more precise, and more cost-effective. The use of 3D printing in dentistry continues to grow, offering significant advantages over conventional techniques.

In this article, we will explore the revolutionary breakthroughs in dental applications of 3D printing and how they are reshaping the future of oral healthcare.

1. Personalized Dental Implants: A Perfect Fit

Traditionally, dental implants required a lot of manual work and could take several weeks to be produced in a laboratory. Thanks to 3D printing, the process has become far more efficient and personalized.

A. Custom Implant Design

3D printing allows for the design and creation of custom dental implants based on precise 3D scans of a patient’s mouth. The digital models created using intraoral scanners or CBCT (Cone Beam Computed Tomography) scans can be directly used to produce implants that fit perfectly with a patient’s natural anatomy. This eliminates many of the potential issues of discomfort, improper fit, or complications that can arise with standardized implants.

- Tailored to the Individual: Each implant is designed to match the patient’s bone structure, ensuring better osseointegration (the bonding between the implant and bone) and a more natural-looking result.

- Reduced Surgery Time: Since implants can be produced with extreme precision, the dental procedure itself is faster and more straightforward, reducing the length of surgery and recovery time for patients.

B. Increased Success Rate

The accuracy of 3D-printed implants significantly improves the long-term success rate of the procedure. With traditional methods, implants sometimes needed to be adjusted due to small mismatches in fit. With 3D printing, these issues are minimized, leading to fewer revisions and a better outcome overall.

2. Rapid Creation of Crowns, Bridges, and Veneers

The production of dental crowns, bridges, and veneers traditionally involved multiple appointments, taking impressions, and sending them to an external laboratory for fabrication. The process could take days or even weeks. With 3D printing, these restorations can be created in a fraction of the time.

A. Single-Visit Restorations

3D printing allows dentists to design and print crowns, bridges, and veneers in a single visit, dramatically cutting down the waiting time for patients.

- Speed: Using advanced materials like resin or ceramics, 3D printers can create durable and aesthetic crowns or bridges while you wait.

- Precision: The use of CAD (Computer-Aided Design) software combined with 3D printing ensures that the restorations fit perfectly, reducing the need for adjustments and increasing patient satisfaction.

B. High-Quality Materials

With 3D printing, a wide range of materials can be used to create restorations. These materials include:

- Resins: Used for creating temporary crowns or bridges that are highly aesthetic and functional.

- Ceramic: Strong, durable, and aesthetically appealing, making it ideal for permanent crowns, bridges, and veneers.

This technology not only makes the creation of dental restorations faster but also ensures that they are of the highest quality, with a precise fit and color matching.

3. Efficient Orthodontic Models and Appliances

3D printing is transforming orthodontics by enabling faster and more customized creation of braces, aligners, and other orthodontic appliances. The traditional process of making orthodontic models and retainers involved using impressions, which could be uncomfortable and imprecise. With 3D printing, orthodontic devices can be produced with much more precision.

A. Custom-Made Clear Aligners

One of the biggest breakthroughs in orthodontics is the development of clear aligners, such as Invisalign, which are 3D-printed to fit each patient’s teeth perfectly. These aligners can be customized based on a 3D scan of the patient’s teeth, ensuring that each aligner is tailored to move the teeth step-by-step toward the desired position.

- Improved Comfort: 3D-printed aligners are more comfortable than traditional metal braces, as they are made from smooth, clear plastic that fits snugly over the teeth.

- Faster Treatment: Aligners can be printed quickly, and because the patient wears a series of aligners over time, this can lead to a more predictable and faster treatment.

B. Custom Orthodontic Brackets and Wires

3D printing allows orthodontists to design customized brackets and wires that better conform to a patient’s individual needs. By using digital impressions and 3D printing technology, custom orthodontic appliances can be created with enhanced accuracy, improving the effectiveness and comfort of treatments.

- Precision and Fit: Custom-made brackets and wires ensure that the pressure on teeth is evenly distributed, leading to more efficient movement and better results.

- Personalization: 3D printing gives orthodontists the flexibility to design unique orthodontic appliances based on the patient’s dental anatomy.

4. 3D Printing for Dental Prosthetics and Dentures

For patients who require dentures or prosthetic teeth, 3D printing offers a fast and cost-effective solution. Traditional dentures can take weeks to produce, and they require multiple fittings to ensure comfort and proper function. 3D printing has changed this, allowing for rapid, high-quality denture creation.

A. Customized Dentures

3D printing can create dentures that are specifically tailored to the unique shape and size of a patient’s mouth. This reduces the time it takes to make the dentures and eliminates many of the issues associated with poorly fitting dentures, such as irritation or discomfort.

- Faster Production: With 3D printing, dentures can be created in a matter of hours or days instead of weeks.

- Improved Comfort and Fit: Since 3D models of the patient’s mouth are used to design the dentures, they fit more comfortably than those created with traditional methods.

B. Affordable Prosthetics

The ability to print dentures and other prosthetics in-house allows dental practices to significantly reduce costs associated with outsourcing. This can translate to lower treatment costs for patients and more affordable options for those who need dental prosthetics.

5. Dental Surgical Guides for Precision Placement

One of the most revolutionary applications of 3D printing in dentistry is the creation of surgical guides for procedures like dental implant placement. These guides are used to ensure that dental implants are positioned accurately and with precision, which is crucial for long-term success.

A. Accuracy in Implant Placement

Using 3D scans of the patient’s mouth, a dental surgeon can create a custom surgical guide that helps them place implants in the exact location they need to be. This guide ensures that the implant is positioned with optimal precision, improving the chances of successful osseointegration (bone bonding) and reducing the risk of complications.

- Reduced Risk of Errors: With a custom surgical guide, the chances of misplacement are reduced, leading to more predictable outcomes.

- Faster Procedures: Because the guide is pre-designed based on the patient’s anatomy, the actual surgical process is more efficient, reducing surgery time and patient discomfort.

6. Creating High-Quality and Detailed Dental Models

Dental professionals need accurate models to plan procedures, from restorative treatments to orthodontics. Traditionally, dental models were created using impressions that could be prone to errors. 3D printing, however, allows for the creation of highly detailed and accurate models of a patient’s teeth, gums, and jawbone structure.

A. Quick and Accurate Models

With 3D printing, dental professionals can create physical models based on digital scans of a patient’s mouth. These models provide a precise representation of the patient’s anatomy and can be used for:

- Implant Planning: Accurate models help in pre-planning implant surgeries.

- Orthodontic Treatment: Clear aligners and other appliances can be designed based on 3D models of the patient’s teeth.

B. Improved Treatment Planning

The high level of accuracy achieved with 3D models allows dental professionals to plan complex treatments more effectively. These models can also be used to simulate potential outcomes, providing a clearer understanding of the expected results before the procedure begins.

Conclusion

3D printing has introduced several groundbreaking advancements in the field of dentistry, making dental treatments faster, more efficient, and more personalized. From creating custom dental implants and prosthetics to designing clear aligners and orthodontic appliances, 3D printing technology has opened up new possibilities for improving the quality of care patients receive. These innovations not only streamline dental processes but also improve patient outcomes, providing a level of precision and comfort that was previously unattainable.

As 3D printing technology continues to evolve, it is likely that even more revolutionary applications will emerge, further enhancing the capabilities of dental professionals and transforming the patient experience.

Discussion about this post