Introduction

In the modern era of dentistry, 3D printing is rapidly transforming the landscape of dental care. One of its most exciting applications is in the creation of dental restorations, such as crowns, bridges, and dentures. 3D printing offers a more efficient, precise, and often more comfortable alternative to traditional methods. But how does 3D printing work for dental restorations, and why is it considered a significant improvement over conventional techniques? In this article, we will explore the entire process of 3D printing dental restorations and highlight its advantages over traditional methods.

1. The Process of 3D Printing in Dental Restoration

1.1 Initial Consultation and Imaging

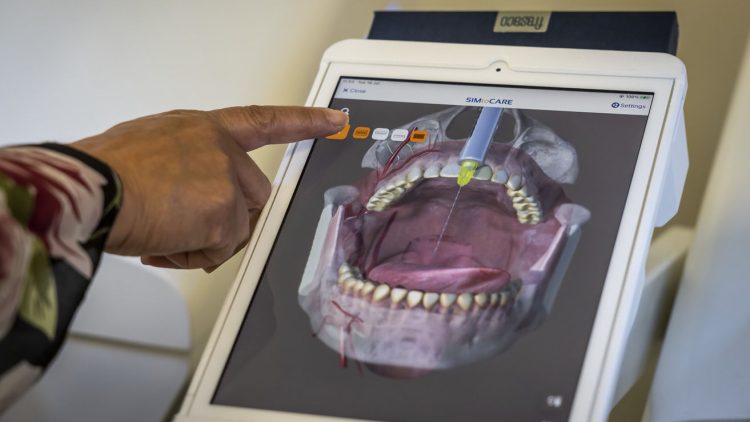

The journey to a 3D printed dental restoration begins with an initial consultation. During this visit, the dentist assesses the patient’s oral health and decides if a restoration is necessary. Traditional dental impressions are often uncomfortable and involve the use of putty. However, with 3D printing, digital impressions are taken using intraoral scanners. These scanners use light or laser technology to create a detailed, accurate map of the teeth and gums, eliminating the need for uncomfortable physical molds.

1.2 Digital Design (CAD)

Once the digital impression is captured, it is sent to a Computer-Aided Design (CAD) system. In this step, the dentist or dental technician uses specialized software to create a highly detailed design of the restoration. The CAD system allows for fine-tuning, ensuring the restoration will fit perfectly and meet the specific aesthetic and functional needs of the patient. Since the design is entirely digital, there is no risk of human error that often occurs with traditional manual methods.

1.3 Material Selection

Choosing the right material for the restoration is essential for ensuring both durability and aesthetics. Common materials used for 3D printed dental restorations include:

- Resin: Typically used for temporary crowns or dentures.

- Zirconia: A strong, durable ceramic often used for crowns, bridges, and other restorations.

- Acrylic: Frequently used for dentures and partial dentures, providing a more comfortable fit.

The material is selected based on the type of restoration being produced and the patient’s specific needs.

1.4 3D Printing Process

Once the design is ready and the material is selected, the 3D printer gets to work. The restoration is created layer by layer as the printer uses the chosen material and follows the precise digital design. Depending on the technology used, the material may be cured with a laser or UV light to solidify it. The process typically takes a few hours, with the exact time varying based on the complexity and size of the restoration. Unlike traditional methods, which involve many manual steps and waiting times, 3D printing speeds up the creation of custom dental solutions.

1.5 Post-Processing

After the printing is complete, the restoration undergoes post-processing. This can involve cleaning to remove any excess material, additional curing to strengthen the structure, and polishing to ensure the restoration has a smooth, natural appearance. At this point, the restoration is ready for fitting.

1.6 Fitting and Placement

During the final step, the dentist will carefully fit the 3D printed restoration into the patient’s mouth. Since the restoration has been created with a high level of precision, fitting it is often quicker and more accurate than with traditional restorations. If any minor adjustments are needed, the dentist can make them on the spot. Once the restoration fits perfectly, it is either bonded or cemented into place, completing the procedure.

2. Advantages of 3D Printing for Dental Restoration

2.1 Enhanced Precision and Accuracy

One of the most significant benefits of 3D printing is its precision. Traditional methods often rely on physical molds and manual work, which can lead to slight inaccuracies. These inaccuracies may not be immediately noticeable but can affect the fit and comfort of the final restoration. In contrast, 3D printing allows for highly accurate, digital impressions and designs, ensuring that the restoration fits the patient’s mouth perfectly. This enhanced accuracy leads to fewer adjustments and a more comfortable fit.

2.2 Faster Turnaround Time

Traditional dental restorations often require multiple visits to the dentist. First, an impression is taken, then a temporary restoration is placed while the final one is created in a lab. This can take several weeks, leading to prolonged treatment time. In contrast, 3D printing significantly reduces this timeline. Many restorations can be designed, printed, and placed in a single visit. This faster turnaround time is especially advantageous for patients who need immediate solutions.

2.3 Less Invasive Procedure

Traditional methods often require significant tooth preparation, such as drilling or reshaping natural teeth, to ensure the restoration fits properly. With 3D printing, dentists can work more conservatively, preserving more of the natural tooth structure. This results in less discomfort during the procedure and a faster recovery time for the patient.

2.4 Customization and Aesthetic Results

The digital nature of 3D printing allows for complete customization of the restoration. The dentist can adjust the size, shape, and color to match the surrounding teeth. The result is a highly aesthetic restoration that blends seamlessly with the patient’s natural smile. Traditional methods often require manual adjustments to achieve a similar result, which may not always be as precise.

2.5 Reduced Risk of Human Error

Since the process of creating the restoration is fully digital, the likelihood of human error is drastically reduced. Traditional techniques, such as taking manual impressions and working with molds, can lead to errors in shaping and fitting. These errors often result in additional visits for adjustments or even the need to remake the restoration. 3D printing eliminates these common issues, providing a more efficient and accurate solution.

2.6 Durability and Long-Term Value

3D printed restorations are often made from highly durable materials, such as zirconia or resin, which are designed to withstand the daily wear and tear of chewing and biting. These materials are not only durable but also biocompatible, meaning they won’t cause adverse reactions in the patient’s mouth. Additionally, because 3D printing often eliminates the need for a temporary restoration, the patient doesn’t have to worry about wearing something that might break or degrade over time.

3. How Does 3D Printing Compare to Traditional Dental Restoration Methods?

Traditional Methods:

Traditional dental restorations, such as crowns, bridges, and dentures, typically involve several steps:

- Impression Taking: The dentist takes physical impressions using materials like putty.

- Dental Lab Work: The impressions are sent to a lab, where a technician creates the restoration using materials like porcelain, metal, or acrylic.

- Multiple Visits: Patients usually have to visit the dentist multiple times for fittings and adjustments.

While traditional methods are effective, they are often time-consuming and require a lot of manual work, which increases the chances of inaccuracies. Moreover, traditional restorations may require more adjustments during fitting, leading to discomfort for the patient.

Comparison to 3D Printing:

3D printing offers a significant improvement in terms of time efficiency, precision, and patient comfort. The process is digital, reducing the chances of errors and allowing for a faster turnaround. Additionally, 3D printing can provide a more natural aesthetic result due to its highly customizable nature. In many cases, restorations can be completed in one visit, eliminating the need for multiple appointments and temporary restorations.

4. Challenges and Considerations

While 3D printing offers many benefits, it’s not without challenges. One of the main concerns is the initial cost of acquiring 3D printing equipment, which can be expensive. However, over time, the cost per restoration is generally lower due to the efficiency and reduction in labor costs. Additionally, 3D printing technology is still evolving, and certain complex restorations may still require traditional methods.

Another consideration is the choice of materials. While 3D printed restorations are durable, some materials may not be as strong as those used in traditional restorations, such as full-metal crowns. As technology advances, however, it is likely that the range of available materials will continue to expand, making 3D printing even more versatile.

Conclusion

3D printing is revolutionizing dental restorations by offering faster, more accurate, and less invasive procedures compared to traditional methods. The precision and customization it provides make it an ideal solution for patients seeking high-quality restorations with minimal discomfort. While there are challenges, particularly with the initial investment and material limitations, the benefits of 3D printing in dentistry far outweigh the drawbacks. As technology continues to evolve, it is likely that 3D printing will become an even more integral part of dental care, providing patients with better, faster, and more affordable solutions.

Discussion about this post