For over a century, the standard workflow for a dental crown followed a predictable, multi-step path: prepare the tooth, take a messy impression, insert a temporary crown, and send the impression to a lab. The patient would return weeks later for the final cementation, hoping the lab-made crown fit perfectly. This process was not only time-consuming but also prone to inaccuracies at every stage—from impression material shrinkage to temporary crown failure. The rise of Chairside Computer-Aided Design/Computer-Aided Manufacturing (CAD/CAM) systems has fundamentally shattered this archaic model. By bringing the design and fabrication of dental restorations directly into the dental office, this technology has orchestrated a seismic shift in restorative dentistry, prioritizing efficiency, precision, and unparalleled patient convenience.

This transformation is not merely about a new piece of equipment; it is a complete overhaul of the clinical workflow, enabled by advanced materials and driven by a powerful set of advantages for both the practice and the patient. This article will dissect the streamlined digital workflow of chairside CAD/CAM, explore the robust materials that make single-visit dentistry possible, highlight the dramatic improvement in patient turnaround time, and detail the comprehensive advantages that are making this technology the new standard of care.

The Digital Assembly Line: The Chairside CAD/CAM Workflow

The power of a chairside system lies in its integration of three key components into a seamless, in-office assembly line. The entire process, from tooth preparation to final seating, is condensed into a single appointment.

- Digital Impression (Data Acquisition): The process begins with the elimination of traditional putty impressions. Using an intraoral scanner, the dentist captures a highly accurate, full-color 3D digital model of the prepared tooth and the opposing dentition. This scan is instantly available on the computer screen, allowing the dentist to verify the preparation’s quality from all angles immediately.

- Computer-Aided Design (CAD): The digital scan is imported into the design software. Here, the dentist or a trained assistant designs the restoration—be it a crown, inlay, onlay, or veneer. The software often includes biogeneric intelligence; it can reference a vast database of natural tooth forms to automatically propose a restoration that matches the patient’s occlusion and anatomy perfectly. The dentist then refines the proposed design, adjusting contacts, contours, and margin placement with precise digital tools.

- Computer-Aided Manufacturing (CAM): Once the design is finalized, the software sends the digital file to a compact milling unit located in the office. A pre-manufactured, high-strength ceramic block (called a “blank”) is loaded into the mill. Using diamond burs, the milling machine precisely carves the restoration out of the solid block of ceramic, typically in 5 to 15 minutes, depending on the restoration’s size and complexity.

- Sintering/Staining and Characterization (if needed): For extremely strong materials like zirconia, a brief sintering cycle in a special oven may be required to achieve final strength and translucency. For other materials like hybrid ceramics, the milled restoration may be stained and glazed to match the patient’s tooth shade perfectly before being polished.

- Try-in and Cementation: The finished restoration is tried in the patient’s mouth. Due to the precision of the digital process, the fit is almost always exceptional. After any minor adjustments and with patient approval, the crown is permanently cemented—all in the same visit.

The Building Blocks: Advanced Materials for Single-Visit Dentistry

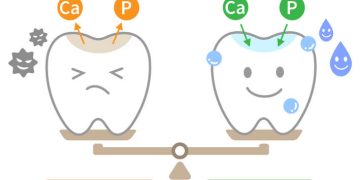

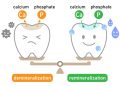

The feasibility of this rapid workflow hinges on the development of millable dental materials that are both machinable in their pre-cured state and exceptionally durable once processed.

- Zirconia: This is the workhorse of strength. Modern translucent or multi-layered zirconia offers a combination of immense fracture resistance and improved aesthetics, making it suitable for single crowns and even multi-unit bridges. It is milled in a “soft,” pre-sintered state and then hardened in a sintering oven.

- Lithium Disilicate (e.g., IPS e.max CAD): Renowned for its excellent balance of strength and lifelike aesthetics, lithium disilicate is a popular choice for anterior crowns and veneers. It is milled in a blue-state stage, then crystallized in a furnace to achieve its final strength and translucency.

- Resin-Based Hybrid Ceramics (e.g., CERASMART, Lava Ultimate): These are composite blocks filled with a high percentage of ceramic particles. They are milled ready-to-use, require no firing, and are known for their toughness, low wear on opposing teeth, and ease of adjustment and repair. They are ideal for inlays, onlays, and single crowns.

- Feldspathic Ceramics: These are the most aesthetic, offering unmatched translucency and vitality, mimicking natural enamel better than any other material. They are typically milled as veneers for the front teeth but are less strong than the other options.

The Patient Revolution: Drastic Turnaround Time

The most tangible benefit for the patient is the radical compression of treatment time. What was once a multi-week process is now accomplished in a single, typically two-hour appointment.

- Elimination of the Temporary Crown: This is a monumental benefit. Temporary crowns are prone to debonding, can allow for tooth sensitivity, and often have poor marginal fit, which can lead to decay or gum inflammation. With a chairside system, the patient leaves with their final, permanently cemented, and perfectly fitting restoration.

- One Appointment, One Anesthesia: The entire process is completed under a single administration of local anesthetic. This means one round of numbness, one trip to the office, and one block of time taken out of the patient’s schedule.

- Instant Gratification and Peace of Mind: Patients experience the psychological boost of seeing their tooth restored to full function and aesthetics immediately. There is no anxiety about the temporary crown failing or waiting to see if the lab-made crown will fit.

The Holistic Advantage: Benefits for the Practice and Clinical Outcomes

The advantages of chairside CAD/CAM extend far beyond patient convenience, offering profound benefits for the dental practice and the quality of care.

- Unmatched Precision and Superior Fit: The digital workflow eliminates the cumulative errors of traditional impressions and model pouring. The result is a restoration with a marginal gap that is often significantly smaller than that of a traditionally fabricated crown, reducing the long-term risk of recurrent decay and cement washout.

- Total Clinical Control: The dentist has complete oversight of the entire process. They can design the restoration to their exact specifications, ensuring optimal occlusion and emergence profile without relying on a third-party lab technician’s interpretation.

- Enhanced Practice Efficiency and Profitability: By producing restorations in-house, the practice eliminates lab fees and captures that revenue. It also streamulates the schedule by condensing two appointments into one, freeing up valuable operatory time.

- A Powerful Practice-Builder: Offering “a crown in a single visit” is a significant competitive advantage that attracts new patients and dramatically increases patient satisfaction and loyalty.

Conclusion: The New Standard of Care

The rise of chairside CAD/CAM systems marks a definitive transition from analog uncertainty to digital predictability. It is a technology that delivers a “triple win”: for the patient, it means unparalleled convenience and comfort; for the dentist, it offers total control and improved clinical outcomes; and for the practice, it drives efficiency and growth. By integrating a digital workflow, advanced materials, and in-office manufacturing, chairside CAD/CAM has moved from a luxury for early adopters to an essential component of a modern, patient-centric dental practice. It has redefined not just how we make a crown, but what a patient can rightfully expect from their dental care experience.

Discussion about this post