For decades, the process of getting a dental restoration followed a familiar, often cumbersome, script: messy impressions, anxious waiting for a lab to craft the piece, and temporary fittings that never felt quite right. This traditional pipeline, reliant on manual skill and postal services, is now being fundamentally disrupted by a technology that builds objects layer by microscopic layer. 3D printing, or additive manufacturing, has moved from a futuristic novelty to a core technology quietly revolutionizing dental practices worldwide. It is transforming not just how dentists create things, but what they can create, offering unprecedented levels of speed, precision, and customization. This article delves into the digital dental revolution, exploring the stunning array of objects now emerging from in-office printers, the profound benefits for both practitioners and patients, and the breathtaking future innovations that promise to make today’s dentistry look archaic.

1. The Digital Dentist’s Toolkit: A Universe of Printed Restorations and Appliances

The scope of what can be 3D printed in a modern dental practice is vast and expanding rapidly, moving far beyond simple models.

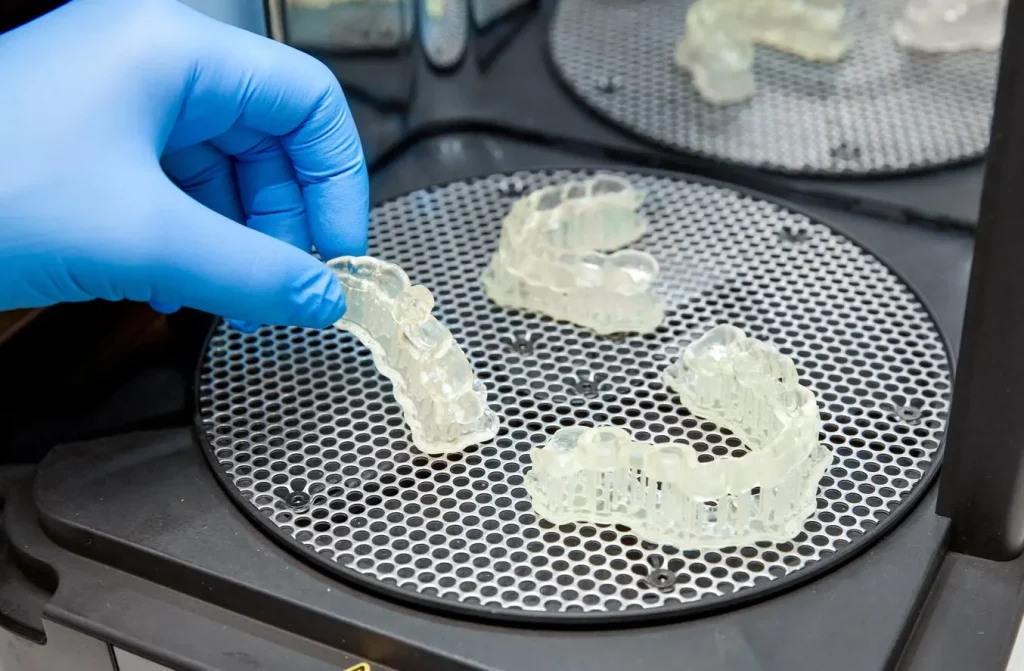

Surgical Guides: This is one of the most impactful applications. Using a patient’s CT scan data, dentists can now print perfectly fitting surgical guides. These transparent, custom-fit appliances sit directly on the patient’s gums and have precisely placed holes that dictate the exact angle, depth, and position for dental implant placement. This transforms implant surgery from a freehand procedure into a predictable, minimally invasive one, drastically improving safety and success rates.

Crowns, Bridges, and Inlays/Onlays: While milling (subtractive manufacturing) is still common for permanent crowns, 3D printing is rapidly catching up. Using high-strength, ceramic-filled resins, dental labs can now print permanent restorations that rival milled ones in strength and aesthetics. The technology is particularly advantageous for complex, multi-unit bridges that would be difficult or wasteful to mill from a single block.

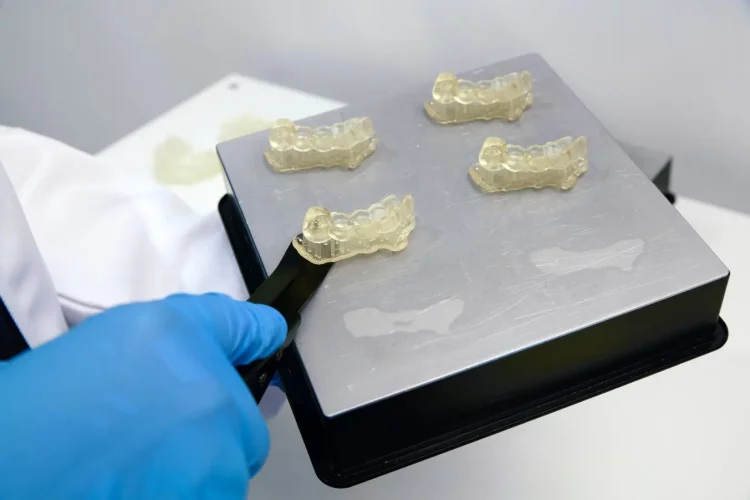

Dentures and Partial Dentures: The traditional denture-making process is labor-intensive and can require multiple appointments. 3D printing streamlines this dramatically. A digital scan of the patient’s mouth is used to design and then print the denture base and teeth in a single, seamless process. The result is a better-fitting, more durable, and highly aesthetic prosthesis in a fraction of the time.

Clear Aligners: The entire clear aligner industry, led by companies like Invisalign, is built on 3D printing. A digital treatment plan generates a series of 3D models representing each stage of tooth movement. A printer then creates a precise physical model for each stage, over which a clear plastic aligner is thermoformed. Some systems are now moving towards directly printing the aligners themselves.

Models and Night Guards: The most common entry point for 3D printing in dentistry is the production of study models and custom night guards. Instead of pouring plaster into an impression, a dentist can simply print a perfectly accurate model from a digital scan. Similarly, a comfortable, perfectly fitting night guard can be designed and printed in-house while the patient waits.

2. The End of the Two-Week Wait: Revolutionary Speed and Efficiency

The single most tangible benefit for patients is the dramatic compression of treatment timelines. What once took weeks can now often be accomplished in a single day.

Same-Day Dentistry: With an in-office 3D printer and a digital scanner, a dentist can now perform what was once unthinkable: a crown in one visit. The process is seamless: the tooth is prepared, a digital impression is taken, the crown is designed on-screen (CAD), and then sent to the printer. While the crown is printing and being cured, the patient can wait comfortably. The crown is then polished and cemented, all within a couple of hours. This eliminates the need for a temporary crown, a second appointment, and the associated anxiety.

Streamlined Workflows: For dental labs and practices, 3D printing is a massive efficiency booster. A single printer can run overnight, producing dozens of models, surgical guides, or denture bases simultaneously. This batch processing slashes labor costs and turnaround times, allowing labs to handle more cases faster and with greater consistency than a team of human technicians could ever achieve manually.

Rapid Prototyping: If a dentist is planning a complex cosmetic case, they can now print a diagnostic “mock-up” of the proposed new smile for the patient to try in. This allows for adjustments and patient feedback before any permanent work is done, ensuring ultimate satisfaction.

3. The Perfection of the Pixel: Unmatched Accuracy and Customization

3D printing eliminates the inherent inaccuracies of the analog world, replacing them with digital precision.

Goodbye to Messy Impressions: Traditional impressions can gag patients, and are susceptible to distortions from bubbles, tears, or improper setting. These inaccuracies lead to ill-fitting restorations that require time-consuming adjustments at the chairside. A digital intraoral scan, in contrast, captures a perfect, millions-of-pixels-accurate 3D model of the mouth in minutes, with no discomfort.

Perfect Fit, First Time: A restoration printed from a perfect digital model is, by definition, a perfect fit. The microscopic-layer accuracy of modern dental printers ensures that margins are tight, contacts with adjacent teeth are ideal, and the bite is correct. This reduces the need for adjustments, saves clinical time, and increases the long-term prognosis of the restoration by preventing microleakage and recurrent decay.

Hyper-Personalization: Because each item is built individually from a digital file, mass customization is the norm. A 3D-printed denture can have personalized gum shading and tooth characteristics. A surgical guide can be designed to protect critical anatomical structures like nerves and sinuses with sub-millimeter precision. The restoration is not just for a tooth; it is for your tooth, in your mouth.

4. The Material Revolution: Beyond Plastic – A New World of Bio-Compatible Inks

The capabilities of 3D printing are directly tied to the materials available. The evolution from basic plastics to advanced, specialized resins has been explosive.

Photopolymer Resins: This is the most common material for many dental applications. These liquid resins harden (cure) when exposed to specific wavelengths of light from the printer. They are now highly specialized:

- Model Resins: For creating accurate study models.

- Surgical Guide Resins: Biocompatible, sterilizable resins that are strong enough to be used during surgery.

- Temporary Crown & Bridge Resins: Durable, aesthetic materials for long-term temporary restorations.

- Crown and Bridge Resins: High-strength, ceramic-filled resins that can be used for permanent restorations, often hardened further in a curing oven.

Metal Printing (SLM/DMLS): For permanent crowns, partial denture frameworks, and implants, metal printing is a game-changer. Using technologies like Selective Laser Melting (SLM), printers fuse fine layers of cobalt-chrome or titanium alloy powder with a laser to create incredibly strong, dense, and precise metal frameworks. This allows for designs that are impossible to cast traditionally, such as lighter, lattice-like structures that are still immensely strong.

The Future of Materials: Research is fervently focused on “bio-active” materials. Scientists are developing resins that can release fluoride ions to prevent decay, or scaffolds that are impregnated with growth factors to encourage bone regeneration. The ultimate goal is printing a living tooth—a goal that remains distant but is actively being pursued.

5. The Next Frontier: From Printed Teeth to Regenerative Dentistry

The trajectory of 3D printing in dentistry points toward even more profound changes that will blur the line between technology and biology.

Bioprinting for Tissue Engineering: The most exciting frontier is the 3D printing of living tissues (bioprinting). Researchers are experimenting with printing scaffolds using biocompatible materials and “bio-inks” containing a patient’s own cells. The goal is to print gum tissue for grafts, periodontal ligament structures, and even entire tooth buds that could mature into functional teeth.

Personalized Pharmaceuticals: Imagine your dentist printing your post-operative medication. 3D printers can create dissolvable films containing precise, personalized doses of pain relievers, antibiotics, or even compounds to promote healing, all in a single patch.

AI-Optimized Designs: The future of dental CAD design will be heavily assisted by Artificial Intelligence. An AI could analyze a digital scan and automatically design the ideal crown morphology for a patient’s specific bite, or generate the most biomechanically sound implant structure, which would then be sent directly to the printer.

Fully Digital, Automated Practices: The dental practice of the future will be a fully integrated digital workflow. From the moment a digital scan is taken, AI-driven software will design the restoration, which is then sent to an in-office printer for fabrication, with minimal human intervention required, maximizing efficiency and standardization of quality.

3D printing is not merely a new tool; it is a fundamental paradigm shift. It is moving dentistry from a craft-based, analog discipline to a digital, engineering-based science. It empowers dentists to provide care that is faster, more comfortable, more accurate, and more personalized than ever before. While the whirring sound of a printer may not be familiar in every dental office today, it is undoubtedly the sound of the future—a future where your smile is restored with the precision of a pixel and the power of a printer.

Discussion about this post